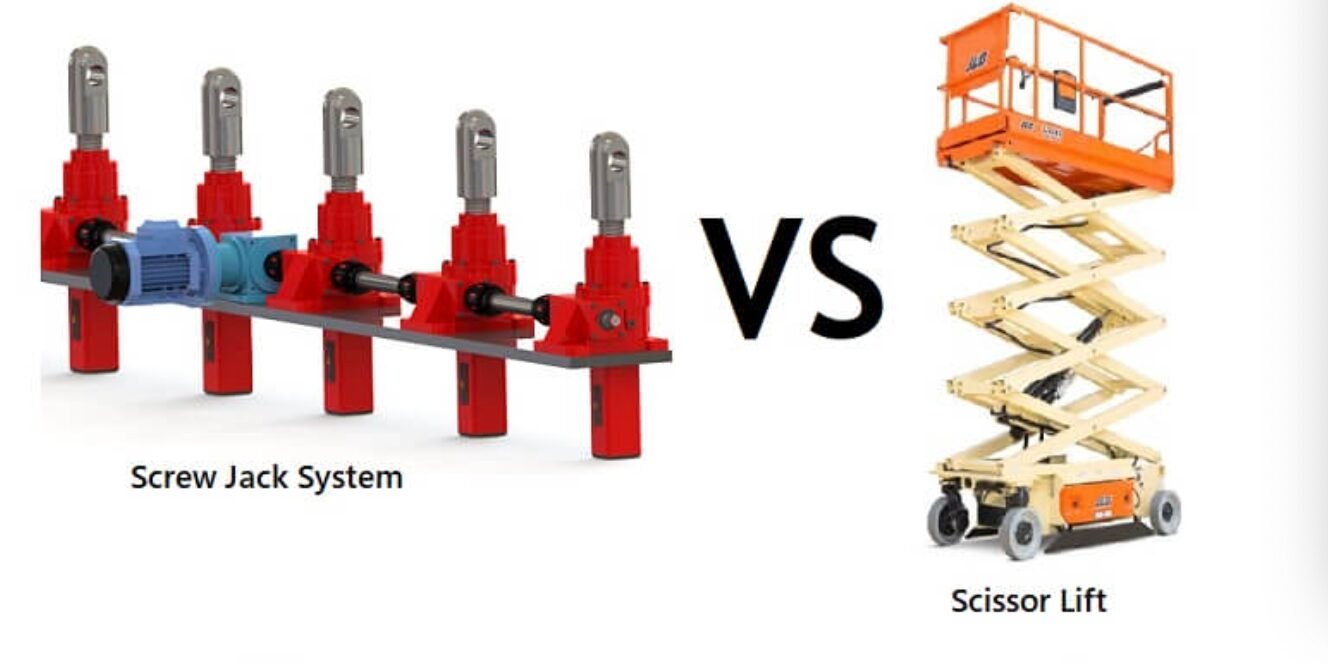

Today, a customer ask me: l am curious, what are the differences between screw jacks system and scissor lift? l mean botha re lifting mechanisms, what is the advantage of screw jacks over scissor lifts? This is a great question! Both screw jacks systems and scissor lifts are used for lifting, but they differ significantly in mechanism, applications, and advantages. Let’s dive deeper into engineering comparison.

1.Mechanical Principles Behind Each system

Screw Jack system

- Working Principle:converts rotary motion into linear motion using a lead screw, ball screw, or worm gear mechanism.

- Key Components:

- Lead Screw or Ball Screw: The core lifting mechanism.

- Worm gear and worm shaft: generate high torque & lifting force.

- Motor cearbox: Provides torque to rotate the screw.

- Casting: Holds and protects the internal components.

- common configurations:

- Single Jacks: For lifting small loads.

- Multiple Jacks in synchronization: For evenly distributing loads (e.g., 4-screw or 6-screw systems in industrial applications).

Scissor lift

- Working Principle: Uses a folding arm mechanism (x-shaped linkage)powered by hydraulic, pneumatic, or electromechanical actuators.

- Key components:

- Scissor Arms: Expands or contracts to provide lift.

- Hydraulic cylinder or Actuator: Provides force to extend/retract the arms.

- Base Frame: Supports the structure.

- Platform: The working area for lifting people or objects.

- Common Configurations

- Fixed Base Scissor Lift: Used in warehouses, assembly lines.

- Mobile Scissor Lift: Used in construction, maintenance.

2.Technical comparison: Performance &Engineering Aspects

Technical Comparison: Performance & Engineering Aspects

| Feature | Screw Jacks System | Scissor Lift |

|---|---|---|

| Lifting Mechanism | Uses a lead screw or ball screw to convert rotary motion into linear motion for lifting. | Uses scissor arms with hydraulic or mechanical actuation to extend and retract. |

| Power Source | Powered by electric motors, manual cranks, or hydraulic motors. | Powered by hydraulic cylinders, electric actuators, or pneumatic systems. |

| Load Handling | Can lift extremely heavy loads (10 + tons to 200 + tons). | Limited by the mechanical constraints of the scissor arms, usually up to a few tons. |

| Precision & Positioning | Provides micrometer-level precision due to the lead screw mechanism. | Less precise due to hydraulic pressure variations and linkage flexibility. |

| Load Stability | Extremely stable, does not sway or bounce. | Can experience instability at higher elevations. |

| Multi-Point Synchronization | Perfectly synchronized using multiple jacks & a control system. | Difficult to synchronize multiple units accurately. |

| Maintenance | Minimal maintenance, no hydraulic fluid leakage. | Frequent maintenance required (hydraulic oil leaks, pressure loss, cylinder failures). |

| Environmental Considerations | Works in extreme temperatures, dust-free environments. | Hydraulic models may not work well in cold or extreme conditions. |

| Service Life | Longer service life (10-20 + years with proper maintenance). | Shorter lifespan, especially for hydraulic components. |

3. Key Advantages of Screw JackSystem Over Scissor Lift

High Load capacity

- Screw jacks can lift extreme loads (100+ tons), whereas scissor lifts are limited due to the mechanical constraints of the scissor arms.

- Example: Heavy-duty industrial presses, aerospace lifting platforms.

Precise Positioning and Repeatability

- Screw jacks provide precise motion control (millimeter-level accuracy).

- Scissor lifts rely on hydraulics, which are harder to fine-tune due to fluid pressure variations.

- Example: Satellite dish positioning, precision assembly lines.

Multi-Jack synchronization

- Multiple screw jacks can be perfectly synchronized using a servo motor control system.

- Scissor lifts struggle with multi-point synchronization, leading to uneven lifting in large platforms.

- Example: Large industrial workstations, stage lifting platforms.

No Hydraulic oil, No leaks

- Screw jacks operate without hydraulic fluid, meaning no risk of leaks, contamination, or fluid degradation.

- Hydraulic scissor lifts require periodic fluid replacement and can leak, causing environmental concerns.

- Example: Cleanroom lifting systems, food-grade equipment.

Long-Term Durability& Lower Maintenance

- Screw jacks have a much longer lifespan with minimal wear and tear.

- Hydraulic scissor lifts require frequent maintenance on seals, hoses, and pumps.

- Example: Permanent lifting applications in manufacturing plants.

4. When to Choose a Screw JackSystem Over a Scissor Lift?

Screw Jack System is Best For:

1.Heavy-duty lifting (10+ tons)

- Example: Heavy machinery lifting, aerospace applications.

2. High precision and repeatability

- Example: Precision positioning for assembly lines, testing0platforms.

3. Multi-point synchronized lifting

- Example: Large-scale industrial equipment that requires even lifting at multiple points.

4.clean environments (food, medical, clean rooms)

- Example: Medical device assembly, lab equipment positioning.

5. Long service life, minimal maintenance

- Example: Structural adjustments in factories, permanent installations.

Scissor Lift is Best For:

1. Temporary lifting needs

- Example: Construction, maintenance, warehouse work.

2. Fast lifting and lowering

- Example: Loading docks, moving workers or equipment quickly.

3.Cost-sensitive applications

- Example: Budget-friendly lifting solutions where precision is not critical.

4. Mobile applications

- Example: Aerial work platforms, cherry pickers.

5. summary: which one is Right forYou?

Summary: which one is Right for You?

| Requirement | Best Choice |

|---|---|

| Heavy load (10 + tons)? | Screw Jacks System |

| High precision (millimeter level)? | Screw Jacks System |

| Multi-point synchronized lifting? | Screw Jacks System |

| Clean environment (no oil leaks)? | Screw Jacks System |

| Temparary, mobile use? | Scissor Lift |

| Fast lifting and lowering? | Scissor Lift |

| Budget-friendly, short-term use? | Scissor Lift |

Final Thoughts

If you need precise, heavy-duty, synchronized lifting with minimal maintenance, a screw jacks system is the better choice. If you need fast, temporary lifting for workers or materials, a scissor lift is more practical.

Would you like recommendations for a specific lifting project? Let me know, and l can suggest an ideal solution!